- An adaptive hydroponics garden.

- Sign In

- Create Account

Alongside the teachers and students from LEAP 5 High School, a greywater-fed hydroponics garden was designed and tested in Santa Clara with the intention of implementing the complete system in South Africa during Spring 2020. To address alternative agriculture, hydroponics is a method that supports plants’ roots in nutrient-rich water instead of traditional soil farming. To further address freshwater insecurity, the system would employ LEAP’s kitchen 5 sink wastewater (greywater) to supply the garden when water levels drop due to evaporation and evapotranspiration.

Implementing alternative farming systems requires community engagement and ownership to ensure the success and longevity of the technology. One of the central focuses of this project was STEM education and student involvement. Thus, 15 hours of lectures, activities, and experiments were designed to connect the fields of Biology, Biochemistry, Environmental Science, and Engineering to the on-site construction of the hydroponics system. The educational materials were developed to be implemented over a 5-day period (3 hours of instruction/day) with 20 student ambassadors at LEAP 5.

The education piece had three main learning objectives: 1) to understand how climate change will impact both humans and plant survival, 2) to understand how the hydroponics system functions and be able to maintain it, 3) to empower students to make a positive impact in their own local communities. Lessons on plant biology and photosynthesis, biochemistry, ecosystem ecology, and climate science connected to different aspects of the hydroponics system. Plant biology, in particular, was a central focus of the education materials.

Each lesson plan included two lab experiments or hands-on activities to practice newly learned skills and daily interaction with the hydroponics system to achieve the first two learning objectives. To address the third learning objective, the lesson plans included examples of student-led movements for climate change, such as speeches by Greta Thunberg, to inspire and 6 empower students to address climate change in their school and the larger local community. The educational materials allow for the learning and application of new science and engineering concepts while providing an opportunity for students to improve local agricultural systems.

When starting a hydroponics farm, a specific type or multiple types of hydroponics systems must be selected. The most prominent types of systems are Nutrient film techniques (NFT), Deep water culture (DWC), Drip irrigation systems, ebb & flow, and wicking. There are other techniques, but this document will not include a discussion of them because they were deemed unsuitable for our desired product.

Deepwater culture systems are extremely simple and are very relevant in the world of commercial farming. DWC is most effective for quick-growing, leafy greens which have significant water needs. The setup for a DWC is extremely simple and requires almost no moving parts and most importantly no water pump to circulate the water. The DWC method only requires that the water be aerated so that enough oxygen is present for the roots to grow. Aeration is obtained by an air pump and airstone in most cases, both of which can be purchased at any aquarium or garden store with hydroponics products. The air pump draws air from the environment and transports it through flexible piping to an air stone which is a configuration of orifices that open up to the water tank containing the plants.

An advantage of DWC growing operations is the maneuverability of the plants even once root systems have matured. The plants float on a styrofoam board (raft) which sits unattached to the water tank. Crops are attached to their own individual substrates which are inserted into holes bored in the rafts. Plants are easily moved by simply pulling the substrate with the root system attached. For the low maintenance, low investment market our group is targeting the DWC method is extremely desirable. These systems are expandable and are only limited by the size of the water tank in which the rafts float in. The DWC systems are suitable for most plants except for long-life plants that require a strong, supportive root base. Plants like squash, zucchini, and tomatoes are therefore not ideal for a DWC system. The largest and most profitable commercial hydroponics companies utilize the DWC systems however because of their low entrance costs and their enormous scalability.

The drip systems require a significantly greater amount of hardware because of the individual drip lines and the accessory piping necessary to transport each stream of water. The narrow drip lines are also prone to clogs if any solid material is encountered, or algae growth occurs. The conditions our hydroponics system will exist in are outdoors so solid contaminants and algal growth may present issues for this type of system.

The team also noted some advantages of Greywater-fed Hydroponics Systems. Hydroponics are preferable to traditional farming methods due primarily to the drastic water savings and efficient use of space. Additional advantages include low upkeep and dramatically fewer pests due to the lack of soil and soil harboring insects and fungus. These advantages are made possible by the recirculating volume of water contained in the walls and pipes of the system. Once the specified volume of water is added to the system, only minuscule amounts are needed to comply with the needs of the plants. The source of these small quantities of water is delegated entirely to the greywater filtration system which requires maintenance no more than once a year.

Certain hydroponic grow beds, especially the raft grow bed, are capable of supporting a plant density approximately five times greater than traditional agricultural methods. The increased density is made possible by the immediate availability of nutrients that are constantly contacting the plants’ roots. In soil, nutrients are dispersed throughout the soil and plants must compete for a finite supply; in hydroponics, nutrients are abundant and their delivery to the plant is expedited. The rapid uptake of nutrients through the nutrient-rich water also supports accelerated plant growth. High entry cost and high complexity are the two most significant detractors preventing widespread hydroponics presence in the agricultural industry. In order for hydroponics to succeed and become a truly disruptive technology the cost to produce such systems and the body of knowledge that supports a simple construction of these systems must be reinforced.

The greywater-fed hydroponics system is significantly less expensive than systems on the market due to the frugal selection of materials and utilization of repurposed materials. Many of the frames and pipes which support the nutrient-rich water can be reused if they are not beyond repair, which has the potential to drive down the initial price of these farms and decrease the duration of time before these systems can return their investment.

The design of the hydroponics system was constructed through a largely iterative process in which physical prototypes were constructed and tested in the Santa Clara University Forge 11 Garden and Civil Engineering Laboratory. Insights from the rapid build and tests provided critical information about the reliability and manufacturability of specific subsystems. Many design decisions were sampled from successful, local farms and verified through physical experimentation at Santa Clara University.

The outdoor hydroponics product our group sought to construct featured multiple grow bed configurations and a self-correcting control system constructed with frugal materials for home and hobby applications with an educational focus. Hydroponics systems do not require any soil to grow and have the capability to scale to a large, commercial application, but our group only examined the smaller scale. Our group has provided educational tools through an output of monitored variables such as temperature, pH, and electrical conductivity, to a smartphone through the use of an Arduino and the app service Blynk.

The monitored variables give the garden owner opportunity to remotely examine the system and study how altering fertilizers and flow rates affect the water quality. The system features a deployable solar shade attached to a rigid frame that activates whenever a thermometer on the grow bed surface reaches a certain high threshold. The shading system allows outdoor gardeners an opportunity to grow a wide range of crops even during the hot summer months. Listed below is a table containing the potential customers we reached out to so that we may better understand the components they find desirable. Tabulating their needs allows our group to directly relate their recommendations to the design of our designed system.

The hydroponics system our design team created features two significant types of input and two types of output. The inputs are separated into continuous and initial inputs. The initial inputs necessary to make the system capable of supporting plants are significant volumes of water and liquid nutrients. Once the system is established with these inputs it requires a consistent flow of electricity to operate the pump, a small volume of water provided by the greywater filtration system, and minimal nutrient solution additions. Additionally, heat in the form of temperature is a continuous input to the temperature sensor attached to the control system.

The outputs realized by the system are primarily the plants harvested at the end of their life cycle. The deployment or retraction of the solar shade is an intermittent output. The outputs related to the shade are based on the current temperature observed by a temperature probe on the surface of the grow beds. The magnitudes of the initial inputs and final outputs are proportional functions related to the size of the grow beds. Larger grow beds require a larger volume of water 13 and liquid nutrients supplied initially. Much like the initial inputs, the single output of harvested crops varies proportionally to the size of the grow beds. A larger grow bed also requires a larger pump, but the scaling is not linear in relation to the area occupied by the grow bed like the water and nutrient volume. Pump sizing is primarily a function of head height observed and the length of pipe that the water must travel to before returning to the pump. The intermittent output realized by the shading system is consistent with the weather patterns of the region and the programmed deployment and retraction temperature.

The established budget contained three main sections accounting for all expected costs resulting from a half-scale hydroponics system at Santa Clara University and a full-scale system at the LEAP 5 high school in South Africa. The major individual contributions came from Santa Clara University, Xilinx, and the Frugal Innovation Hub grant. Crowdfunding was additionally utilized to further raise funds.

Our group has sought funding from the Undergraduate School of Engineering Program for the materials total. The materials detailed in our budget have covered the construction and operational functions of two hydroponics systems - one in Santa Clara, CA, and one in Jane Furse, South Africa. Our Santa Clara prototype allows us to gain hands-on experience with the plumbing, control system, shading structure, and agriculture components. In doing so, our team has gained the knowledge required to optimize the system’s growing conditions. Gaining this knowledge of the complete system has allowed us to replicate the design for LEAP 5 School.

The hydroponics system our group has built consists of five principal subsystems: grow beds, shading structure, data logging, plumbing orientations, and greywater filtration system. Each of the defined challenges of the project was paired with a specific subsystem to overcome these obstacles. Every challenge had to be deliberately addressed in a subsystem in order for our project to be successful.

The grow beds are a focal point of the hydroponics system and the success of the subsystem is the measurement of success for the entire system. Grow beds were required to be durable and capable of rapid construction. The final designs were largely inspired by and adapted from observations recorded during visits to successful large-scale hydroponics and aquaponics farms.

Our team ultimately decided to construct and design two operating systems for our final design. Both manual and automatic operation will be the driving forces for the deployment of the shading material. We created the manual system because we wanted to ensure that our South African system could be easily maintained, reducing the number of electronic components that were ultimately needed for the automatic system. On the other hand, the automatic system would be constructed and prototyped here at Santa Clara University. This motorized system alleviates 35 the duty of monitoring the hydroponics system throughout the day. While the automatic system would be ideal, it was not feasible for manufacturing in South Africa. In both cases, the overall design and construction of the structure are identical.

The automatic shading structure removes the human dependence factor and is instead being driven by inline stepper motors. This motorized system alleviates the duty of monitoring the hydroponics system throughout the day. Motors are attached to the vertical ABS structure and are connected to each other through a horizontal pipe where the shading material wraps around. Both motors work in unison with each other to deploy the shade over the grow beds. Stepper motors were chosen for our application due to the fact that their angle of rotation can be precisely controlled and that they can possess holding torque without the need for the motor to be powered. Through the use of an Arduino, a connected waterproof temperature sensor on the surface of the raft beds constantly monitors the temperature. When the sensor reads a temperature out of suitable range for the vegetables to grow, the Arduino would then send a signal to the stepper motors to rotate to deploy the shading material.

Reviewing the thermal analysis, our team's hypothesis was correct. It was proven that by increasing the shading percent coverage, the styrofoam grow bed’s surface temperature decreased as a result. It should be noted that the temperature of the entire bed will not be as constant as is shown in the CAD simulations (see Appendix B7) due to solar positioning changes throughout the day as well as the vegetables providing some shade to the bed. It can be concluded that a shading material of 50% porosity and higher can be used for our raft grow bed. Since styrofoam is the most widely used grow bed media for hydroponics, we do not believe that we need to test other materials but rather focus on how to provide the ideal growing environments for vegetables that will use this material.

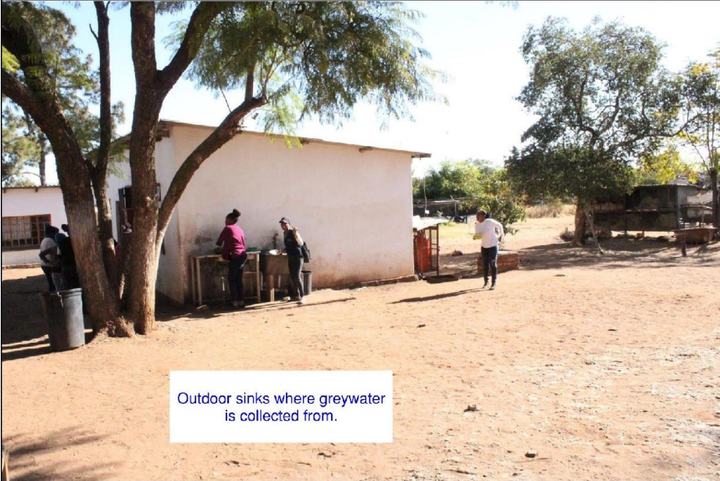

One of the main goals of the project was to conserve water when compared to traditional soil farming. We identified an opportunity to use LEAP’s existing greywater catchment system as our water supply for the hydroponics garden. In general, greywater refers to any wastewater that does not contain fecal matter. In LEAP’s case, they captured water from a dishwashing sink that is routed underground to irrigate a lawn on campus. The scope of the greywater filter is to supplement the water lost due to evaporation and/or leakage. Our team estimated this quantity of water to be about half of the total volume per month (1000 L). Based on LEAP 5’s observed water production conducted by the project team’s contacts, the surge for washing dishes in the kitchen was around 200 L/day. Assuming that this surge would come essentially in one load as the students washed their dishes after lunch, the capacity of the surge tank was set to handle 300 L. Since each round of dishwashing will not be needed to top off the hydroponics garden, a tee-branch is fitted to redirect greywater to water the existing lawn if the hydroponics system does not need to be topped off.

Constructed wetlands are a proven filtration method for greywater and use locally produced and reused materials effectively. An old bathtub would act as the container for the wetland with pipes and reservoirs also being repurposed. A mulched surge tank would provide 51 for the initial filtration of grease and oils coming directly from the kitchen sink. A rhizome network (root system) of native aquatic plants is used in this filter to remove harmful bacteria and nutrients from entering the hydroponics system.

The biggest advantages of this system are the use of recycled materials and the overall simplicity of the system. Maintenance is low except for lowering the water level once a month. Disadvantages include the unknown energy costs associated with transporting the filtered water from the reservoir to the nutrient tank in the hydroponics system.

The early completion of a fully functioning hydroponics system provided our team with one harvest of approximately 40 heads of lettuce. The results were mixed due to limited accessibility to the Forge Garden, yet the romaine and butterhead lettuce fared excellently in the spring conditions.

The success of the lettuce verified that a raft grow bed is capable of supporting a plant density of four plants per square foot with no significant nutrient deficiencies. The beds featured an approximately 80% survival rate with no pesticides and only a single large liquid nutrient addition at the beginning of the life cycle. The liquid nutrients used were entirely organic and sourced from plant extracts. The macronutrients had a balanced NPK and no micronutrients were added. An additional arugula raft was planted but all crops bolted likely due to a specific lack of nutrients. The two types of lettuce fared very well and grew rapidly despite the low macronutrient levels and the lack of micronutrients. Significant plant growth was observed in the wicking bed. Eight tomato plants were planted in the wicking bed and after 60 days all plants survived and expanded rapidly. Metal cages were added to the wicking bed so that the rapidly growing tomato plants would have additional structure to support their stems and stalks when the plant begins to produce tomatoes.

One of the main goals of this project was to conserve freshwater. Instead of utilizing the already limited freshwater source in the Limpopo region of South Africa, our team was determined to solely utilize kitchen greywater to fill our grow beds. A final design of the MulchRetention Filter for the greywater was constructed and tested for water quality using a kitchen sink greywater in Santa Clara. The test determined how effective the filter was to lower the nitrate, nitrite, total hardness, total alkalinity and pH levels of the greywater to prove if it was safe to use in the hydroponics system.

The conservation of clean drinking water was a major focus in the design of the hydroponics garden. Low water usage was made possible through efficient grow beds and a greywater filter to incorporate existing greywater of unknown quality. Energy usage was additionally decreased due to optimal pump sizing and the timer which regulates the uptime of the water pump.

Using our data from the prototype first lettuce harvest, a water savings analysis was conducted to determine the system’s usage compared to a raised bed soil garden. The baseline soil garden assumed the same grow area as the hydroponics garden with a 4-inch depth of irrigation every 4 days. The hydroponics garden is assumed to have replaced ½ the total volume of water each month. With these assumptions in mind, an annual projection of expected produce yields and the gallons of water used per pound were calculated.

The hydroponics garden tested in Santa Clara’s Forge Garden used less than half of the water and produced over two times the yield when compared to a baseline soil garden. Results were gathered from the prototype first romaine lettuce harvest and compared to a Cornell University study’s soil production.

The design and development of a greywater hydroponics system mitigate many negative impacts of conventional agriculture, including the inefficient use of water, large land 59 requirements, dependence on concentrated and toxic pesticides, and soil degradation through erosion.

Several factors were assumed in the construction of the hydroponics system. Most factors were centered around the durability and sustainability of the project. The focus was placed on energy and water savings as well as utilization of commonly available resources. Assumptions are as follows: \u25cf Significantly reduced water usage compared to traditional farming \u25cf Electricity costs that are outweighed by the freshwater water savings and increased crop yield. \u25cf The materials utilized to construct the system are reused as much as possible and are otherwise sustainable in their production. \u25cf Our system will be more environmentally friendly since it is designed to fit the school’s needs rather than retrofitting an existing commercial system for the necessary production size.

Using readily available materials at the school in South Africa as well as a mixture of both plastic and wood, the energy use for our system is significantly lower than that of a commercial system made entirely of plastic and metal. Additionally, the flow design of our system requires only one pump to operate whereas the commercial system needed eight, one for each of the grow beds. Compared to completely packaged, commercial systems our hydroponics product is much less expensive per square foot of grow space and does not rely on entirely new materials. The materials used in constructing our design can be repurposed from past projects and sourced locally. Commercial products on the market do not have this advantage and also must require shipping which amounts to transportation costs and significant emissions. Purchasing a commercial system does provide nearly as much ownership of the system either and if a piece breaks it likely must be replaced using spare parts sold by the 60 company, which will amount to further transportation costs and emissions.

The adaptive hydroponics garden product was created to primarily service local farmers with a limited budget and minimal access to drinking water. The primary stakeholders related to the product benefit from the creative, durable, and adaptable design. The hydroponics product is non-profit and attempts to diminish the barriers so that small, non-technical farmers may utilize the benefits of hydroponics farming.

Regions with limited access to freshwater and agricultural households with limited access to many acres of land are the targeted market for hydroponics. The potential for high-density growth regardless of soil quality is extremely appealing to regions where bountiful harvests may be impossible due to geographic or weather factors. The low price point and highly customizable nature of the systems give the hydroponics farmer the freedom to build and expand what works and move away from what does not. The most significant limiting factor to the hydroponics market is the initial price point. Driving the price down through the use of local and recycled or repurposed goods assists the designed hydroponics system in overcoming the hurdles that have stifled the growth of the industry. The simple design as displayed in the assembly manuals additionally reduces the perceived complexity and improves the durability of the product, granting a reliable sense of ownership to the buyer.

The prime market for the hydroponics product is agricultural households who depend on the stable production of crops to feed their family or sell to generate income. The greater markets are very broad and applicable to the suburban gardener interested in an alternative method, an urban gardener who wants to make good use of their limited growing space in a sustainable manner, or the industrial farm interested in scaling up production without the need for additional harmful chemicals added to the topsoil. The large-scale industrial application is especially beneficial to facilities that have an excess of greywater. The filtration system in series with the hydroponics grow beds provides unmatched energy and water savings. Profits associated with 62 the density and rapid production advantages of hydroponics over traditional methods are scalable, so expansive farms have the potential to generate significantly more revenue. In the financial studies conducted using our product, the density of hydroponics is four times greater than that of traditional soil farming. The expanded yield compounds with the 60% faster growth rates seen in our hydroponics garden compared to soil farming.

The most significant advantage our product displays is due to the collaboration with local farmers who will be the primary stakeholders in the product. The needs expressed by the primarily low-income agricultural community were centered around the durability of the system, a wide range of crops supported, and high yield. These needs were referenced constantly and developed through a dialogue between the stakeholders and the designers of the farming system. The critical local input and high level of adaptability make the product very attractive compared to existing products on the market. Nearly all existing products are very discrete in the materials and the method of construction required to produce the hydroponic system which leaves little room for local specification. The existing markets feature primarily self-contained systems which have significantly higher expenses per yield. The product designed by our team is extremely affordable if the overall yield is compared to the initial costs and the local farmer will regain their investment after just a year and a half of steady production.

The goal of our product is to provide information about hydroponics so that farmers in targeted areas may choose to employ hydroponics and improve their agricultural situation while decreasing their freshwater needs. The objective of the product is to disperse catered information about the benefits of hydroponics through the success of the physical system. The hydroponics system is an effective tool for small or large-scale agriculture to insulate itself from the mounting water scarcity and insecurity in primarily impoverished regions threatened by the effects of climate change.

The primary objective is supported through the significantly lower price point, without compromising quality or production. A lower cost of entry helps dissolve the barriers preventing widespread access to hydroponics systems, especially in impoverished regions. Water is transported from a nondescript 50-gallon barrel, which could 63 be substituted if an existing hard-walled, plastic water container is already available, to two unique grow beds. Each grow bed is capable of growing plants up to four times as densely as traditional farming because of the availability of nutrients in the steady stream of water.

A shading system, either automated or manual, provides climate control for the grow beds and a greywater filter constructed from commonly available materials conditions kitchen wastewater so that it can be inputted into the grow beds' water supply. Our product details specifically how to construct the modular grow beds, shading system, and greywater filter. The sustainability of the product is augmented by the non-physical nature of the system. The designed hydroponics system is not reliant on specific materials, rather it is scaffolding with which to create a customized hydroponics system specific to the environment of the customer. The primary product is information that will lead to successful plant yields, greater than yields that could be accomplished using traditional soil farming. The provided assembly manuals are reflective of our successful experimentation with hydroponics, but the geometries, materials, and sizes of all subsystems are open-ended so that the customer has some creative license given their specific environment.

The hydroponics garden system is reliant on local manufacturability. When designing the project, significant emphasis was placed on rapid manufacturability because the construction window of the flagship system at the LEAP 5 High School in South Africa was only five days. The manufacturability of the system is a potential bottleneck we identified in our eventual construction in South Africa. The bottleneck was investigated and remedied through the construction of a half-scale prototype at Santa Clara University’s Forge Garden. Each subsystem was constructed from start to finish and then verified with a successful crop harvest. Building each component of the system provided a clear picture of the manufacturing duration each component required.

One focus of the designed system is the utilization of recycled or repurposed materials We targeted repurposed materials to build the infrastructure of our system because these materials are often significantly less expensive, they do not require transportation because they 64 are already available, and they promote a sense of ownership for the customer. The LEAP 5 High School explained they could provide us with old bathtubs, excess irrigation piping, mulch, gravel, and soil. We planned to source timber, hardware, and power tools from a local supply store less than a kilometer from the school’s campus. Manufacturing occurs on the side of the customer so as sales expand, greater expenses are not required to support growth. To reach greater markets, more system options could be prototyped and documented so that regions with environments different from arid, warm South Africa could be specified.

To investigate the sustainability and affordability of the system for rural South Africa, an economic analysis was performed to compare the LEAP 5 hydroponics garden design with traditional raised-bed agriculture. Even though the intended use of the final system is for educational opportunities and not for profit, this economic analysis is able to clearly compare the benefits of hydroponics to traditional soil farming. Sustainable initiatives which decrease operations and maintenance costs (O&M) included with the hydroponics garden are the greywater filter and homemade compost nutrient solutions. Yield comparisons were documented using the same growth area and $1.25 as an average sale price of a head of lettuce.

The Raised Bed baseline model had a 24% return on investment with a payback period of under 4.5 years. The LEAP 5 hydroponics design had a 83% return on investment with a Type of System Raised Bed Garden - Baseline Model Hydroponics with Sustainable Initiatives Capital Costs Annual O&M Capital Costs Annual O&M Grow Beds $719.85 $240.53 $802.03 $127.18 Shading System $173.00 $107.48 Data/Logging $217.00 Greywater Filter $118.60 Initial Start-Up Water $0.10 Total Cost $892.85 $240.53 $1,245.21 $127.18 Annual Yield $431.05 $1,068.62 Return on Investment 23.47% 83.17% Payback Period (years) 4.35 1.29 68 payback period of under 1.5 years. Along with the added water savings per pound of produce, the hydroponics garden design is projected to yield $1,068.62 annually. The main reason for a higher yield in the hydroponics system versus raised bed farming was the yield per square foot. The hydroponics system is able to produce four heads of lettuce compared to soil’s one head per square foot.

Due to the COVID-19 pandemic, there were a couple of tests that the project team was never able to run in their entirety. Although the quality of the filtered greywater was determined to be adequate for usage, the greywater filter was never connected to the hydroponics grow beds for their complete testing in a harvest of vegetables. Another item was the nutrient solution. In order to further the system’s sustainable design, an organic-homemade nutrient solution using fermented chicken manure, straw, and water was to be tested for its effectiveness in the system. By using this at the LEAP high school, they could decrease their O&M costs significantly by not having to purchase and ship nutrient solutions each month. The final consideration moving forward would be to test the effectiveness of the product in various climates. We were lucky enough to have a similar climate in Santa Clara to Jane 71 Furse, such that this system would work sufficiently all year in South Africa. However, in order to expand its reach to the LEAP school system, this system may have to be adapted in order to fit different climate zones.

In conclusion, hydroponics is a method of gardening that suspends plants’ roots in nutrient-rich water instead of replacing new soil each harvest. This alternative to traditional, in-ground farming has the ability to significantly reduce pesticide usage, growing area, water usage per plant, and time between harvest and consumption. Greywater refers to wastewater that does not contain fecal matter. By employing filtered kitchen sink wastewater as the primary water source of the hydroponics garden, the water footprint is reduced and the sustainability of the garden is enhanced even further. The greywater-supplied hydroponics garden system designed alongside LEAP 5 High School in Jane Furse, South Africa successfully utilizes sustainable materials, a self-monitoring temperature controls system, a shading system, and greywater input. It was used as an educational tool for students and significantly reduced freshwater use compared to traditional, in-ground agriculture.

The educational material surrounding this system was critical to its success as an inspiration for adopting alternative agriculture for the students at LEAP 5 and the surrounding Jane Furse community. When compared to traditional, in-ground agriculture, our hydroponics system was found to have a much higher payback period and return on the initial investment. The final product also reduced the amount of freshwater usage while utilizing a successful greywater filter which removed harmful surfactants from kitchen wastewater. Along with a retractable shading unit that reduces the number of leafy greens scorched from high temperatures, the prototyped project was a huge success when compared to its traditional farming alternative and will be utilized in the Forge Garden as an educational tool for years to come.

Due to the COVID-19 pandemic, the project team was not able to travel to South Africa for the planned March 2020 implementation at LEAP 5 School. However, all instructional materials will be sent to LEAP 5, alongside do-it-yourself manuals detailing the system’s 72 structure, material selection, and construction sequencing. Incorporating students and the community in the construction of the hydroponics system is essential to the success and longevity of this project. Our greywater hydroponics system was designed to augment LEAP 5’s STEM curriculum and provide an avenue for water savings and food security. This system, designed to be sustainable and self-monitoring, can reduce freshwater use for farming and increase food security for the students and their community. This project was designed to serve as a pilot at LEAP School 5 in hopes that they can extend the knowledge of the system for implementation across the entire LEAP school system and beyond.